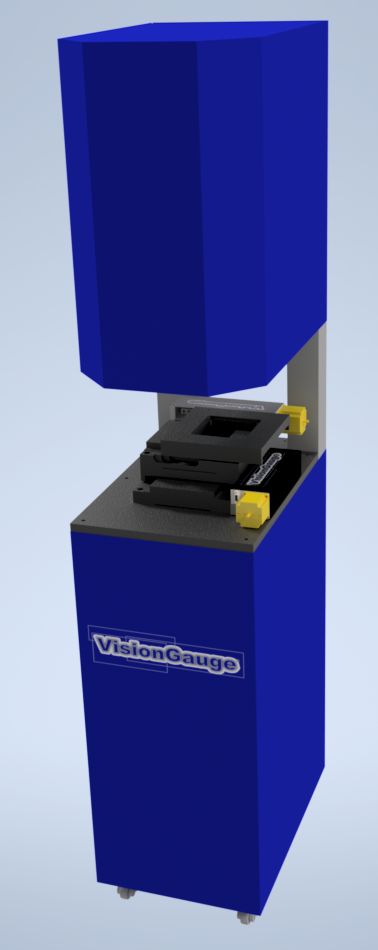

New Compact 500 Series VisionGauge® Digital Optical Comparator – Complete Inspection & Measurement in a Small Footprint (July 2025)

The new Compact configuration of the 500 Series was developed for applications requiring full inspection functionality but where floorspace is …July 24, 2025

1 MIN READ