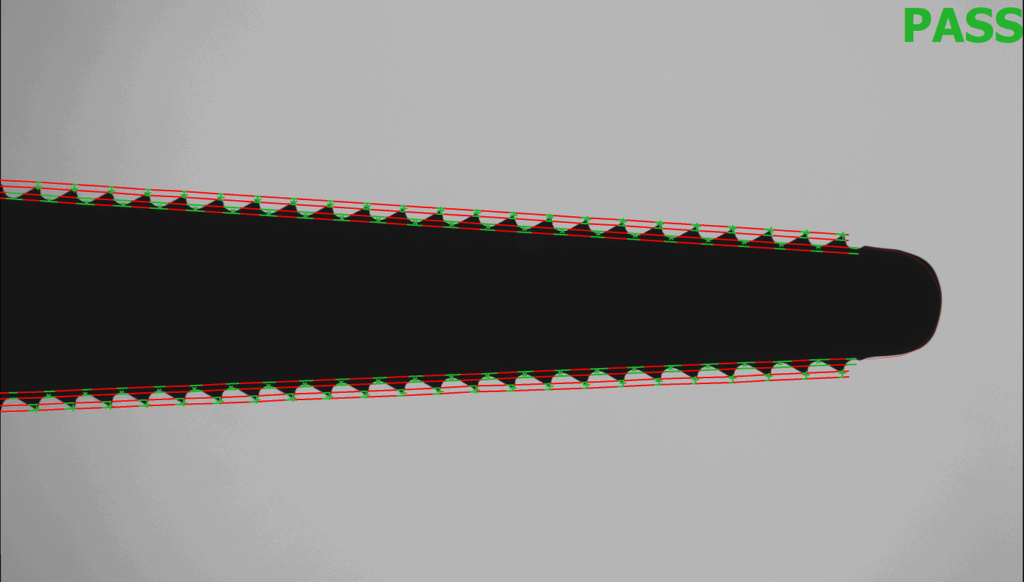

VisionGauge®’s Patented “Tooth Checker™” Tool

VisionGauge®’s Patented “Tooth Checker™” tool is specially adapted to check parts

with teeth

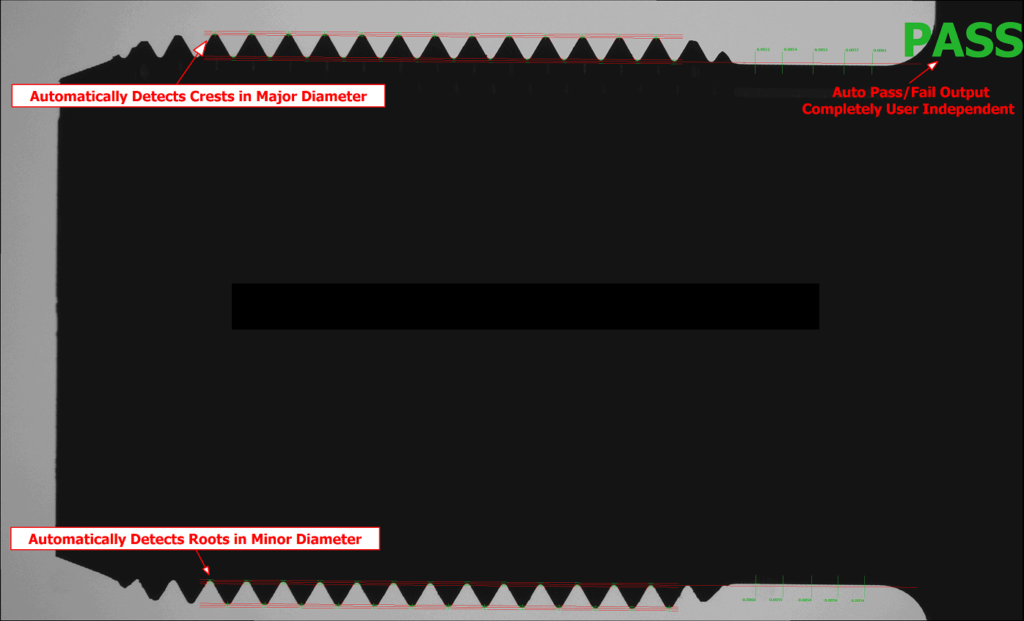

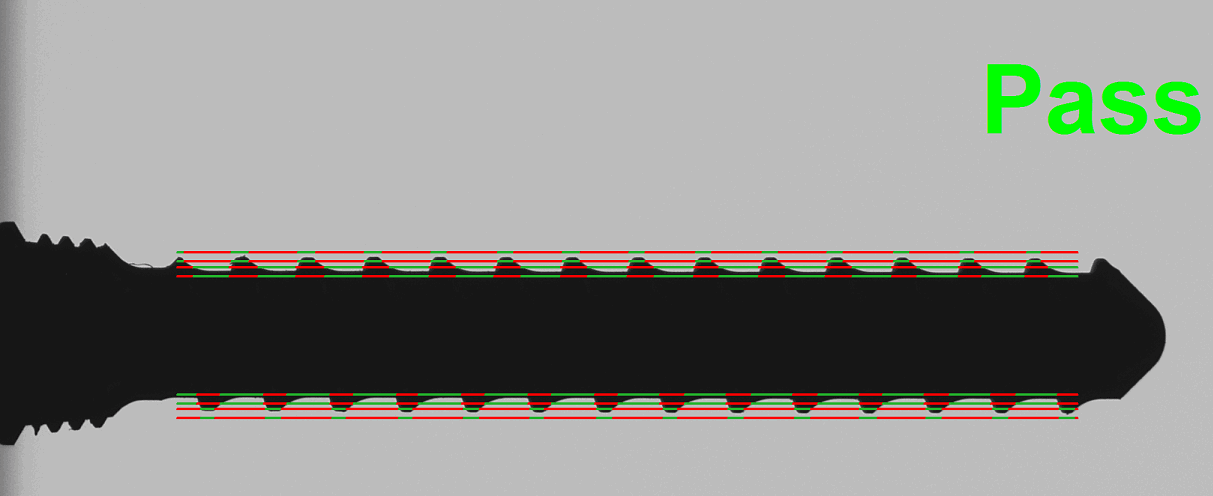

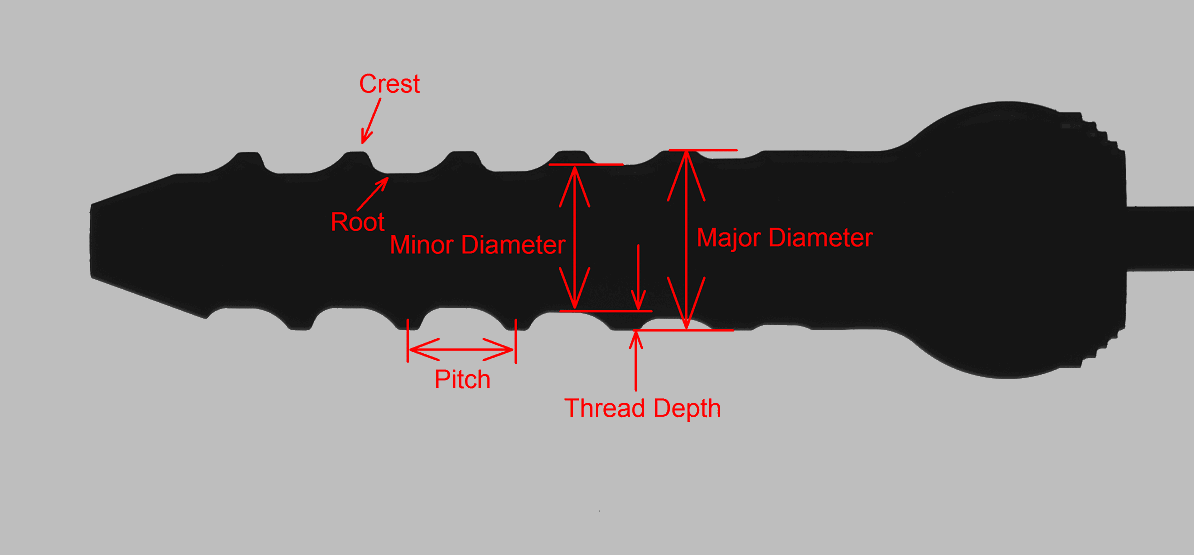

VisionGauge®’s powerful and innovative patented “Tooth Checker™” tool automatically locates, to very high accuracy, the crests and / or roots of a part's teeth or threads and determines if they are within their tolerance band. It can also determine all other part characteristics, such as tooth pitch, thread depth, major & minor diameters, etc...

- Fully automated

- Completely independent of part orientation & clocking

- With a rotary stage the crest and root points can be used to calculate part runout

- Can also be applied to parts that are larger than the field-of-view

- The tool is usable in both manual and fully-automated modes (i.e. within an automated program)

- The tool produces a PASS / FAIL result (which can be exported and used in all of the same ways as the current PASS / FAIL results) and also shows where the part passes and where it fails

- Supports linearly variable tolerances, plus/minus tolerances, plus/plus tolerances, minus/minus tolerances, etc...

- Smart “Adaptive Thresholding” automatically disregards point imperfections

Perfect for quickly and accurately checking:

- Bone screws

- Medical rasps

- Gears

- Fluted Instruments

- Threads & fittings

- Etc...

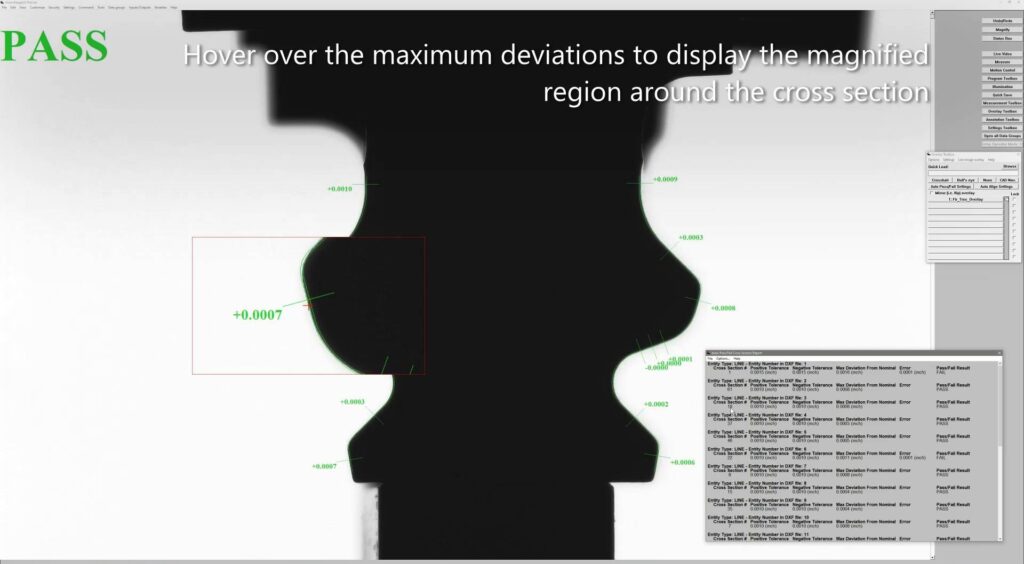

Using the crest & root points that the Tooth Checker tool has found, it can then automatically determine all other part characteristics

Overview Video:

Our new Advanced Analysis and Report tools also allow operators to follow-up a Tooth Checker™ operation to review, explore, and label results at each cross section of interest in the field-of-view.

Download a .pdf version of this VisionGauge® Digital Optical Comparator Application note here.