Parts inspections are essential to your quality assurance processes, especially in the power and energy industry. These components work hard under extreme conditions, so they must meet established industry standards to operate efficiently and, more importantly, safely. VisionGauge® Digital Optical Comparators can aid quality assurance practices by inspecting industrial components with advanced, patented technology.

Industrial Gas Turbine Inspection

Gas turbines work with dangerous combustion systems, so it is crucial to inspect each part that goes into one of these assemblies before moving on to the next stage of production. Our VisionGauge® Digital Optical Comparators are perfect for gas turbine part manufacturing inspection because they allow for precise, accurate evaluation of small, hard-to-reach components.

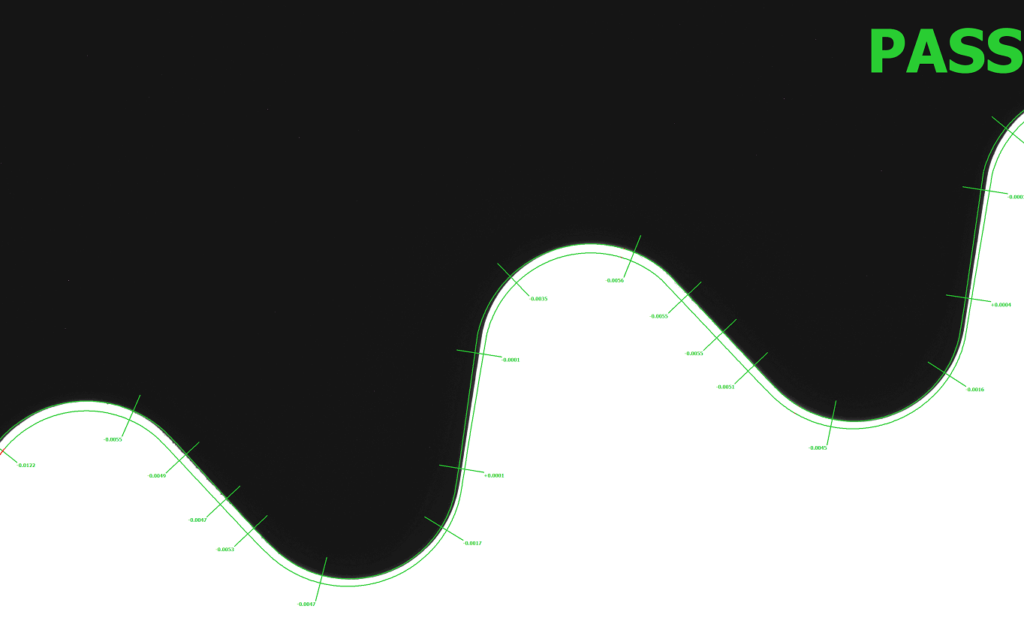

You can conduct your inspections manually or automatically and compare the results to their CAD description without any overlays. We can simplify your industrial gas turbine parts inspection with these unique capabilities from our devices.

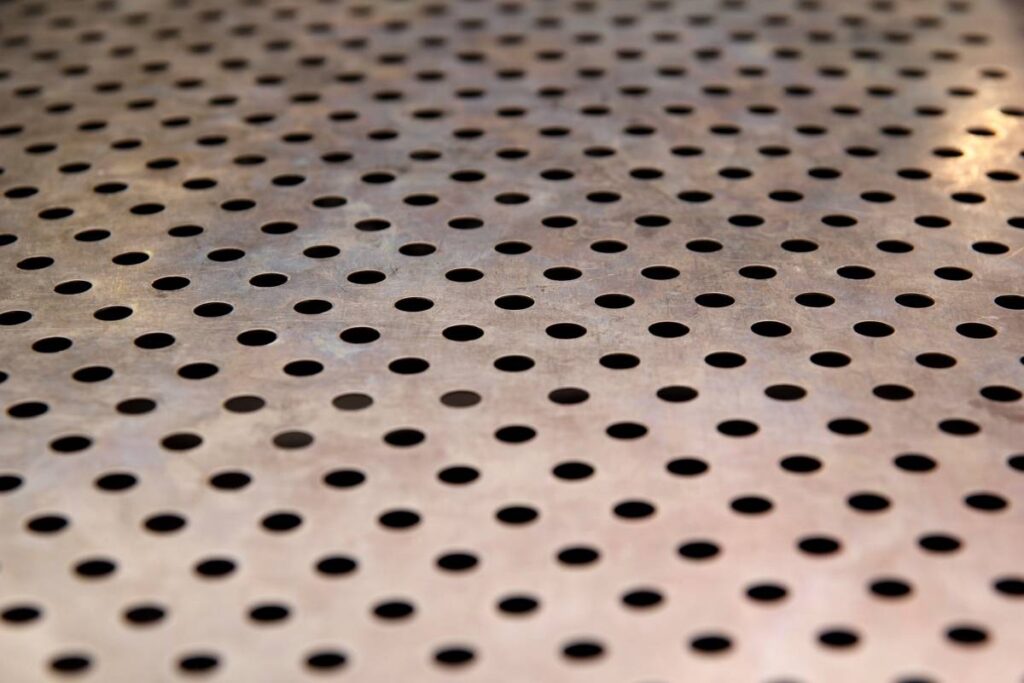

Micro Hole Inspection: Power and energy applications use parts with several small holes, and each one must be checked to ensure every component meets industry standards. Our VisionGauge® Digital Optical Comparators work on various materials, including metal, silicone, carbon, and ceramic.

In the power and energy industry, the ability to inspect small holes is crucial because they play a vital role in facilitating flow in gas turbines. Micro hole inspections check the size, location, and geometry of each hole, as well as the number of holes present, to ensure adequate flow.

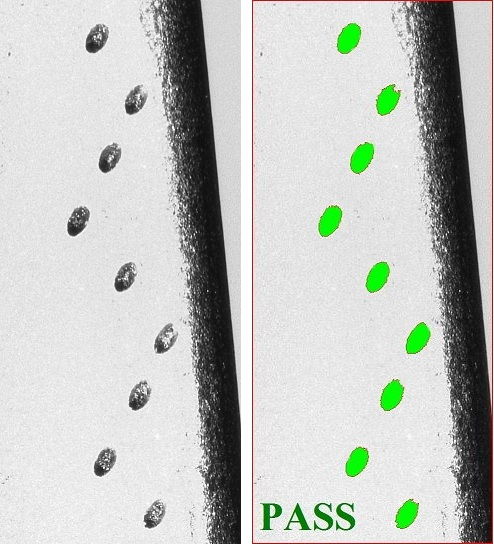

Cooling Hole Inspection: Since gas turbines operate via combustion, they experience high temperatures and require proper cooling systems to maintain safety. To achieve this, manufacturers drill tiny holes into the turbine blades to transfer cool air from inside the blade to its surface. These cooling holes must be the correct size and shape to operate effectively.

VisionGauge® Digital Optical Comparators can inspect these cooling holes quickly and precisely, removing the element of human error. Whether the part has 10 holes or 10,000 holes, our VisionGauge® devices inspect each one thoroughly.

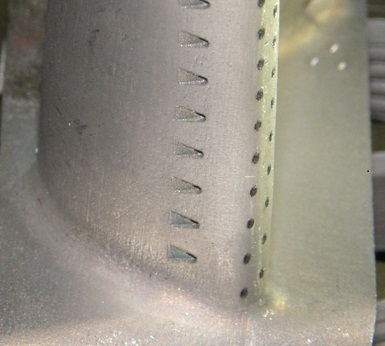

IGT Bucket Inspection: Turbine buckets are some of the hardest-working parts of an industrial gas turbine. These components operate under immense force and high temperatures and are made with extremely tight tolerances, so it’s vital to inspect them thoroughly to ensure they can withstand the demands of their application. We designed our VisionGauge® Digital Optical Comparators specifically for industries that involve requirements of this level. These devices accurately inspect large components and alert manufacturers of any faults or inconsistencies.

Explore Our Inspection System for Industrial Gas Turbines

At VISIONx, Inc., we offer advanced equipment such as the 700 Series VisionGauge® Digital Optical Comparator 5-axis inspection and measurement system. This digital optical comparator is suitable for complex industrial gas turbine parts measurements on precision components such as blades and buckets. Our patented technology is easy to use, allowing you to streamline your day-to-day activities and improve the quality of your manufactured parts.

Contact Us for a Quote

Power and energy experts with the industry’s most stringent quality assurance processes rely on VisionGauge® Digital Optical Comparators. Contact us today to learn more about these inspection systems and how they can fit your needs.