VisionGauge® OnLine version 13.38, dated April 25th, 2019, is available for download.

This update adds greater functionality to working with an overlay position during an automated program:

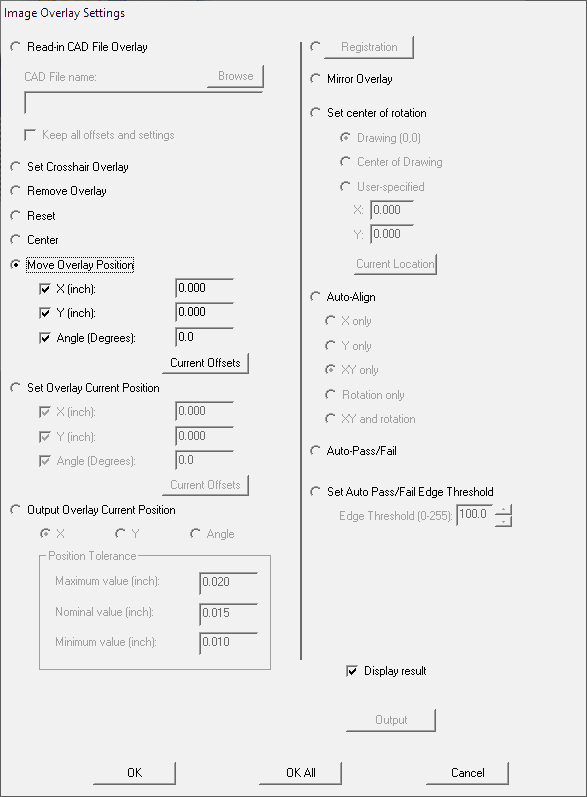

The Image Overlay Settings window has renamed the option to “Set Offset” of the overlay to “Move Overlay Position”.

We have also added the options to “Set Overlay Current Position” and “Output Overlay Current Position”. The Output option requires that you choose which dimension you want to output, the nominal and tolerances on the value, and the Output options (to which Data Group the data will be sent, any label information, etc.). This new Output option could be useful to determine by how much an overlay has shifted, for example, after a Auto-Align procedure.

This update also contains a significant performance improvement that will reduce latency and “waits” at many points during the system’s operation. Specifically, we have enhanced the software to optimize runtime performance, so that when the software is started up it pre-calculates a number of (long-to-compute) coefficients and then re-uses them (instead of re-computing them) when they are required.

The performance improvements that a user will obtain vary depending on the specific system configuration (typically multi-mag systems will benefit most) and also depending on how the system is used (typically, users that frequently switch back-and-forth between manual operation and automated programs should see the greatest benefit from these performance optimizations).

However, it’s worth noting that these are quite “core” performance enhancements and the system should feel “snappier” for almost all users.

Also in this update, we have restructured and greatly improved how ProLink software is used with VisionGauge® OnLine.

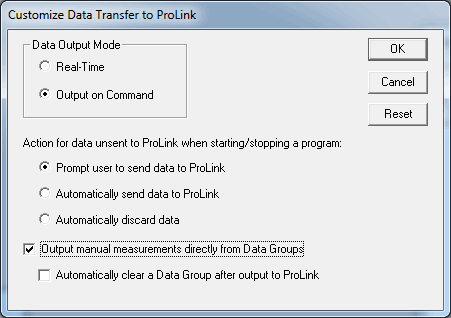

This update introduces the “Output on Command” mode, which is now an option to the default “Real-Time” mode. Real-Time mode sends all data sent to a Data Group to ProLink immediately. Output on Command mode allows a user to accumulate data to a file before sending a command to output all that data to ProLink at once. This helps ProLink group the data for a part and avoids ‘deleted points’ from being inserted in places where ProLink would expect data to exist that did not come in with a file.

Also, “Source” and “Extra” data that are sent with a measurement have been relocated to the measurement specific options. Previously these were defined for the entire ‘machine’, but they are now able to be defined for each measurement. In addition, “Note” data can now be sent with each measurement to better relay information about a measurement in ProLink. As before with Source and Extra data, Notes can be defined as user-selected text, or String/Numeric variables.

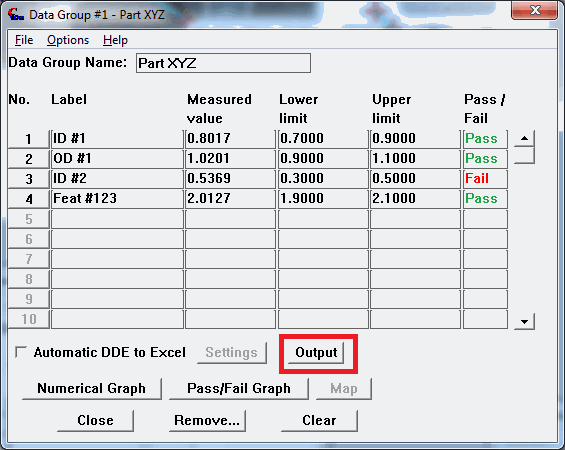

In addition, we made outputting results to ProLink using manual measurements easier by adding the possibility to output results directly from Data Groups. Data for a part can be accumulated in Data Groups and output all at once to ProLink when it is ready. This allows the possibility to change labels and ensure all manual measurements are correct before output.

The complete documentation for setting up and using ProLink software with VisionGauge® OnLine may be found here.