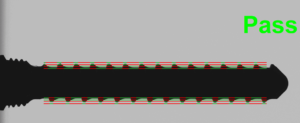

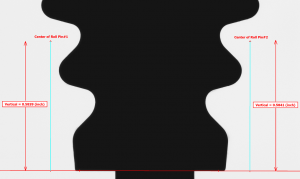

Bone screw teeth can be automatically verified against specs with the VisionGauge® “Tooth Checker™” tool. This new tool automatically locates, to very high accuracy, the crests and/or roots of the teeth and determines if they are within their tolerance band. It can also determine all other part characteristics, such as tooth pitch, thread depth, major & minor diameters, etc…

Media Category: Applications

Images related to applications solved with the VisionGauge Digital Optical Comparator

VisionGauge_Tooth_Checker

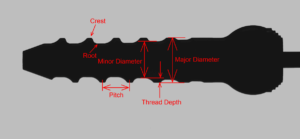

VisionGauge® Tooth Checker Nomenclature

VisionGauge®’s Patent Pending “Tooth Checker™” tool is specially adapted to check parts with teeth. Using the crest & root points that the Tooth Checker tool has found, it can then automatically determine all other part characteristics, including minor and major diameter, pitch, and thread depth.

This tool is perfect for quickly and accurately verifying and inspection bone screws, medical rasps, gears, fluted instrument, threads and fittings, etc.

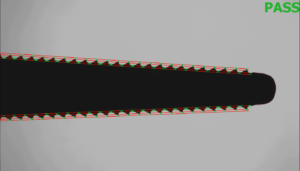

Medical Rasp Inspection and Verification

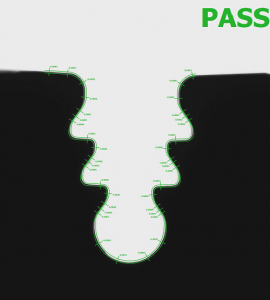

VisionGauge®’s new Patent Pending “Tooth Checker™” tool is specially adapted to check parts with teeth. The Tooth Checker tool can check that either

crests, roots, or both, are in tolerance, perfectly adapted for medical rasp inspection and verification. The tool supports linearly variable tolerances, plus/minus tolerances, plus/plus tolerances, minus/minus tolerances, etc…

Automatic-Thread-Inspection-Crest-Root-Detection

VisionGauge®’s new Patent Pending “Tooth Checker™” is capable of fully automatic thread inspection and verification of teeth/threads to ensure they fall within tolerance. Crests and Roots are detected to a high accuracy, completely independent of part orientation and clocking. The tool produces a Pass/Fail result and shows where the part passes and where it fails. Smart “Adaptive Thresholding” automatically disregards point imperfections.

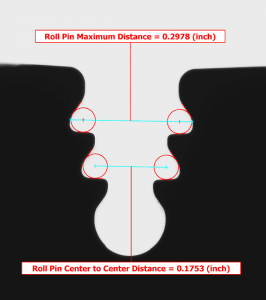

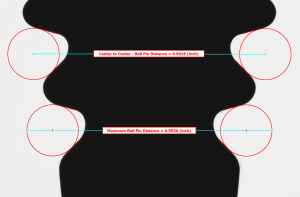

Roll pin measurements

VisionGauge®’s Roll Pin distance measurement tool offers multiple option for roll pin distance gauging for applications such as turbine slot inspection.

Turbine Disk and Slot Inspection Pass/Fail

The VisionGauge® Disk Inspection and Measurement System utilizes VisionGauge®’s patented CAD Auto-Align™ & CAD Auto-Pass/Fail™ tools to automatically compare the part to its CAD drawing and perform measurements to verify if the part is within spec.

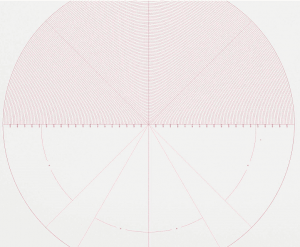

DXF Format CAD Overlay Radius Charts

DXF format CAD overlay radius charts have now been included in VisionGauge® OnLine’s LiveImageOverlay directory. Operators of traditional optical comparators will already be very familiar these charts, and they could be very useful in certain instances with the VisionGauge® Digital Optical Comparator (for example: when inspecting short-arc radii).

Roll Pin Distance Measurement Tool

VisionGauge OnLine’s Roll Pin Distance measurement tool is useful for many different types of inspections, including root forms of blades, root forms of disk slots, gear teeth, thread teeth, etc. This new tool is versatile, very easy to setup and use, and is extremely accurate & repeatable.

Roll Pin Distance Measurement Tool

VisionGauge OnLine’s Roll Pin Distance measurement tool is useful for many different types of inspections, including root forms of blades, root forms of disk slots, gear teeth, thread teeth, etc. This new tool is very easy to setup and use and is extremely accurate & repeatable.