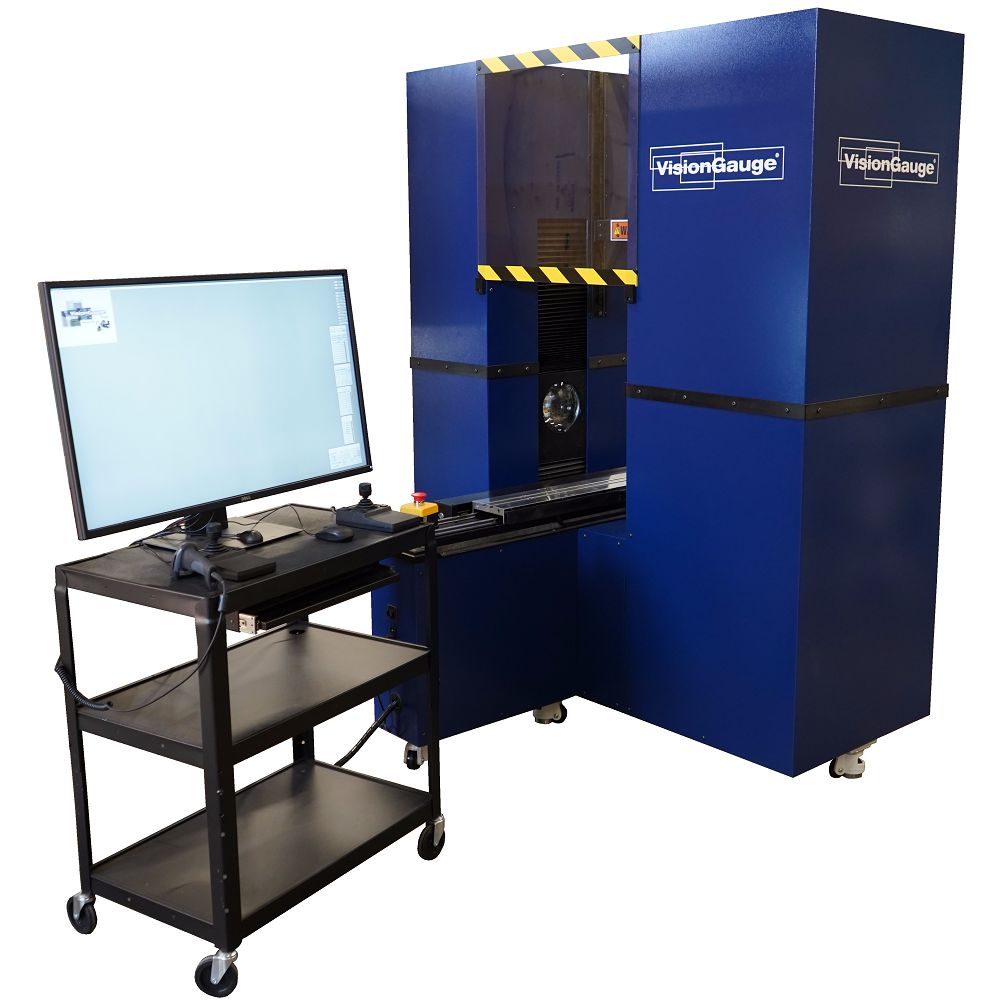

Super-Extended Travel Configurations 500 Series VisionGauge® Digital Optical Comparator

The Super-Extended 500 Series systems are designed to inspect & measure large parts and heavy loads with high accuracy.

- High-accuracy inspection of large parts supporting up to 300 pounds over 60" of travel

- Fast operation for high throughput

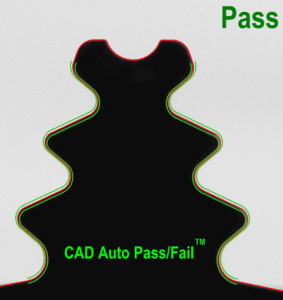

- Includes patented CAD Auto-Align™ & CAD Auto Pass/Fail™ tools

- Works directly with CAD data so that no overlay or template is required

- Automatically computes and displays the part's deviation from nominal and compares it to bi-directional tolerances

- Robust & shop-floor-ready

- High-resolution, high-contrast image with sharp edge profiles to clearly see fine details

- Easy-to-use and easy-to-program with fully automated measurements: no operator-dependent variation!

- Large depth of field and large field-of-view to see more of the part and all in focus at once

- Compare parts to their CAD file beyond the optical field-of-view, across the entire stage!

- Collect full inspection & measurement data for automatic report creation and data exchange

Our Digital Optical Comparator for Large Parts Inspection

The Super-Extended Travel Configuration 500 Series VisionGauge® Digital Optical Comparator is a precision system designed specifically to inspect and measure big and heavy parts. They have up to 60” of travel and support loads of up to 300 lbs!

Parts are set on the system’s X-Axis stage, which is built using precision rails and is set on a floor-mounted granite base. The camera is mounted on the Z-axis and the entire assembly, along with the front and back illumination, move up and down on the Y-Axis. In this way, the Y and Z axes are completely disconnected from the rugged granite-base-mounted X-axis that supports all of the part’s weight. The axes have 0.25µm resolution encoders for high-accuracy positional feedback.

This innovative configuration is designed to provide optimal rigidity and eliminate any mechanical deflections. Everything is optimized to allow the system to produce very accurate measurements of long and heavy parts.

500 Series Super-Extended Travel Configuration Advantages

The system provides all of the advantages of the 500 Series VisionGauge® Digital Optical Comparator and includes additional benefits that make it stand out from the competition:

- Fully-automated: no operator-dependent variation!

- Fast and accurate performance delivering very high throughput

- Extremely easy-to-use for operators and programmers: Little or no programming, i.e. "I've got a part, I've got a CAD file, and I've got a minute"

- Features VisionGauge's patented CAD Auto-Align™ & CAD Auto Pass/Fail™ tools

- Automatically computes and displays a part's deviation from nominal and compare it to bi-directional tolerances

- Produces a beautiful and very high-resolution, high-contrast image with very sharp edge profiles. You can see very fine details very clearly

- Works directly with CAD data so no templates or overlays are necessary - compare a part to its CAD file beyond the optical field of view (because the CAD data tracks the part and follows the stage motion)

- Very robust and shop-floor-ready

- Has all-LED illumination (for very stable & repeatable illumination conditions, very stable & repeatable results, low heat, low power consumption and no bulbs to change)

- Can collect full inspection & measurement data and automatically create reports including digital images & records with the CAD overlay and the deviations from nominal, measurements, statistics, etc...

The system is powerful and widely-applicable - capable of solving a vast number of applications across many industries. In particular, the Industrial Gas Turbine (IGT) / Power Generation industry greatly benefits from the use of this system for inspection of fir trees / root forms on buckets. We can also design and build oversized systems to meet unusual or one-of-a-kind requirements.

Features

The VisionGauge® Digital Optical Comparator 500 Series Super-Extended-Travel Configuration is designed to inspect large and heavy parts with performance, reliability, and high-accuracy in mind.

- 60" of travel for large parts, supporting up to 300 lb loads

- Precision components designed for optimal stability and performance for heavy parts across the entire range of travel

- 0.25µm resolution encoders provide high-accuracy positional feedback

- Includes VisionGauge®'s advanced measurement and inspection toolset to carry out fully-automated measurements, including proprietary software tools for direct CAD-to-Part comparison

- With the system's large depth of focus, "everything is in focus at once", and the large field-of-view means you can see more of the part at once.

- The long working distance gives more clearance between the part & the lens

- Power-Focus and Auto-Focus keep part edges crisp for very accurate measurements

- Super-high resolution monitor allows you to see all the details of the image at once

- Extremely easy to use software interface

- Automated image/data collection and a wide array of reporting and data exchange features

Contact us with your requirements for more information on how the VisionGauge® Digital Optical Comparator 500 Series Super-Extended-Travel Configurations are suited to solve your application.