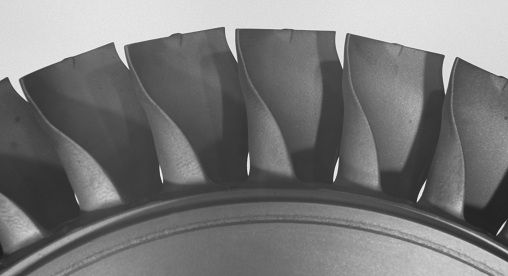

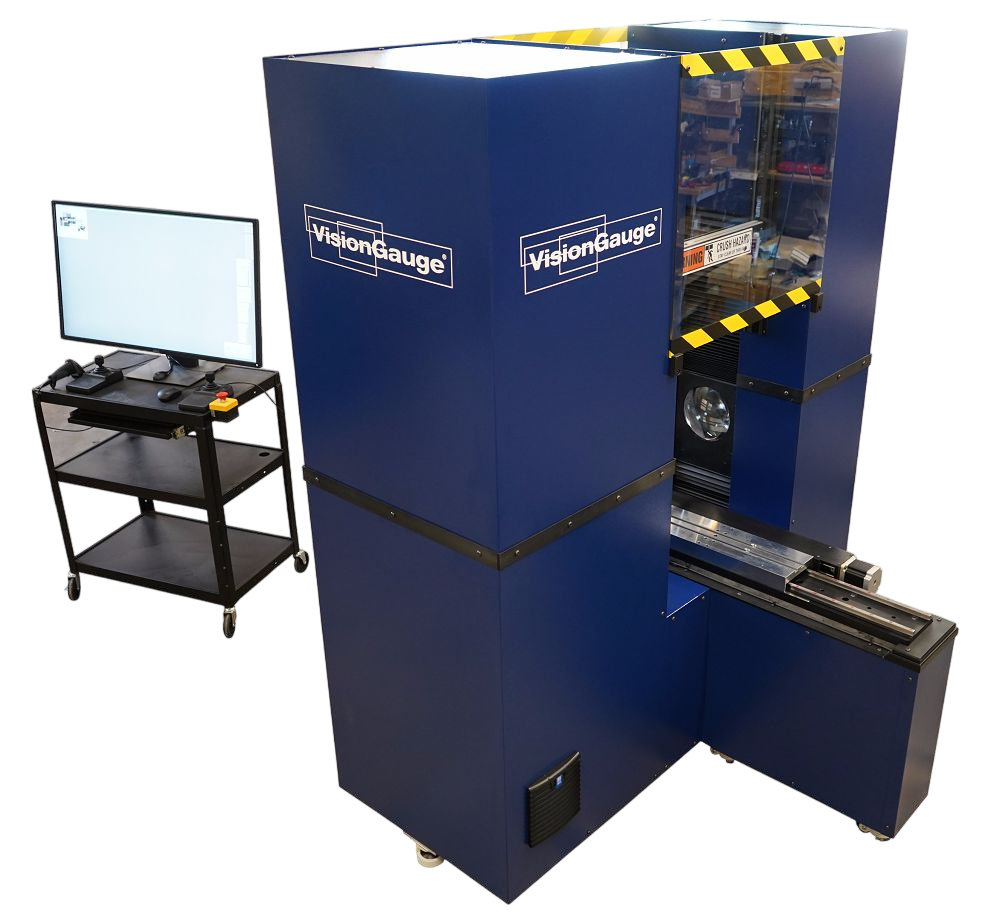

There are many reasons why the VisionGauge® Digital Optical Comparator is widely used by manufacturers in the aerospace and power generation industries for the inspection of turbine disks:

The VisionGauge® Digital Optical Comparator is rapidly becoming the new standard for inspecting turbine disks and broached slots in the aerospace and power generation industries.

Download a .pdf version of this VisionGauge® Digital Optical Comparator Application note here.