500 Series Digital Optical Comparators (Patented and Other Patents Pending)

The VisionGauge® Digital Optical Comparator is The Fastest, Easiest, Most Accurate Way to Compare a Part to a CAD File™

Benefits of the VisionGauge® Digital Optical Comparator:

- Accuracy

- Speed

- Small footprint / uses little floor space

- More powerful than any other existing optical comparator

- The only comparator with "Auto Pass/Fail"

- The only existing fully digital comparator

- The only comparator that can be fully automated

About Our 500 Series Optical Comparator

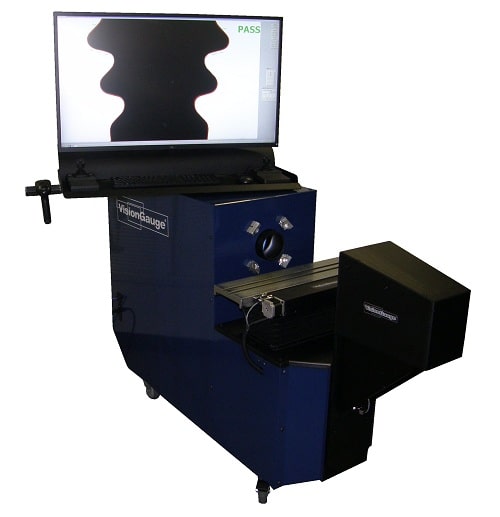

The VisionGauge® Digital Optical Comparator is a fully digital device that works as a reliable drop-in replacement to the traditional optical comparator. It offers convenience for users, allowing you to work directly with your part's CAD file without the need for overlays, templates, or Mylars™.

This digital profile projector is designed with patented technology and sub-pixel accuracy. It lets you perform accurate and precise measurements and efficiently compare parts against their respective CAD drawings. This streamlined functionality effectively shortens the inspection process without compromising precision and accuracy.

The 500 Series is an automated optical comparator that features a robust and extremely easy-to-use technology. It's equipped with the VisionGauge® system's patented CAD Auto-Align™ and CAD Auto-Pass/Fail™ programs, making it easy to use directly on the shop floor. The CAD Auto-Align™ tool automatically aligns the overlay for a fully automated CAD-to-part comparison. Meanwhile, the CAD Auto-Pass/Fail™ tool computes and displays any deviation from nominal and determines out-of-tolerance measurements in real time. In addition to proprietary patented technology, it also has our patent-pending Tooth Checker™ tool to accurately locate roots and crests in toothed parts.

The full digital capability minimizes the device's margin of error and leaves no room for operator mistakes or operator-to-operator variation. It can also collect complete electronic documentation without human intervention. These include all measurements, pass/fail results, statistics, and high-resolution images of every part inspected.

Advantages of Our Profile Projector

The 500 Series Digital Optical Comparator is a powerful and versatile device suitable for measuring both small and large parts. Unlike traditional optical comparators, this machine offers numerous benefits at a competitive price. Benefits include the following:

- High-contrast image with sharp edge profiles for a detailed view

- High level of accuracy

- Excellent optical depth of field capability

- Longer optical working distance between the part and the lens

- LED illumination for stable lighting

- Comprehensive tools for advanced analysis and reporting

- Runs fully automated measurements

- Automatically sends data to Excel and other external applications

- Space-saving and portable

- Features a rolling cart configuration for easy movement without re-calibration

- Automated work cell integration

- Options to control via TCP/IP and RS-232 communications

- Automated CAD comparison beyond the optical field-of-view

- Barcode reader and joystick interface

- Extremely intuitive software

- On-screen measurements

- Quick and easy annual calibration procedure

500 Series Additional Features

The 500 Series VisionGauge® Digital Optical Comparator boasts unique features. Some of its cutting-edge features include the following:

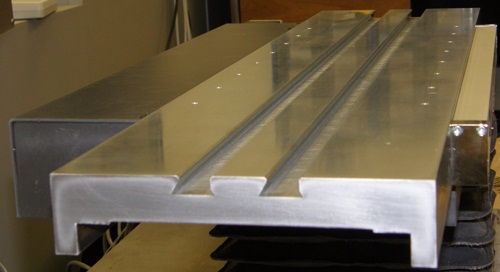

- Standard 12" travel X-axis stage with a 0.5-micron resolution encoder

- Protective bellows around the 6" travel Y-axis column

- Highly accurate crossed-roller movements for all 3 standard axes

- High load-carrying capacity

- Programmable and computer-controlled illumination

- Power focus and auto-focus capabilities in single or multi-magnification configurations

- Complete and ready-to-run Windows-based solutions

- Network-ready upon delivery

- Standard dovetail mounting grooves

- Customizable workholding and fixtures

- Optional high-resolution LASER module

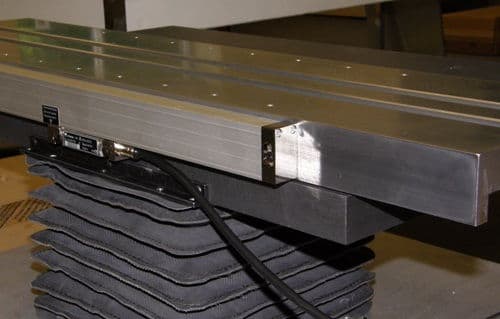

Standard 12" travel X-axis stage with protective bellows around the 6" travel Y-axis column. All 3 axes (X, Y and Z) feature high-accuracy crossed-roller movements for optimal linearity and positional repeatability.

Hard chrome plated X-axis stage, made of hardened tooling steel and with dual standard dovetail grooves for easy part fixturing.

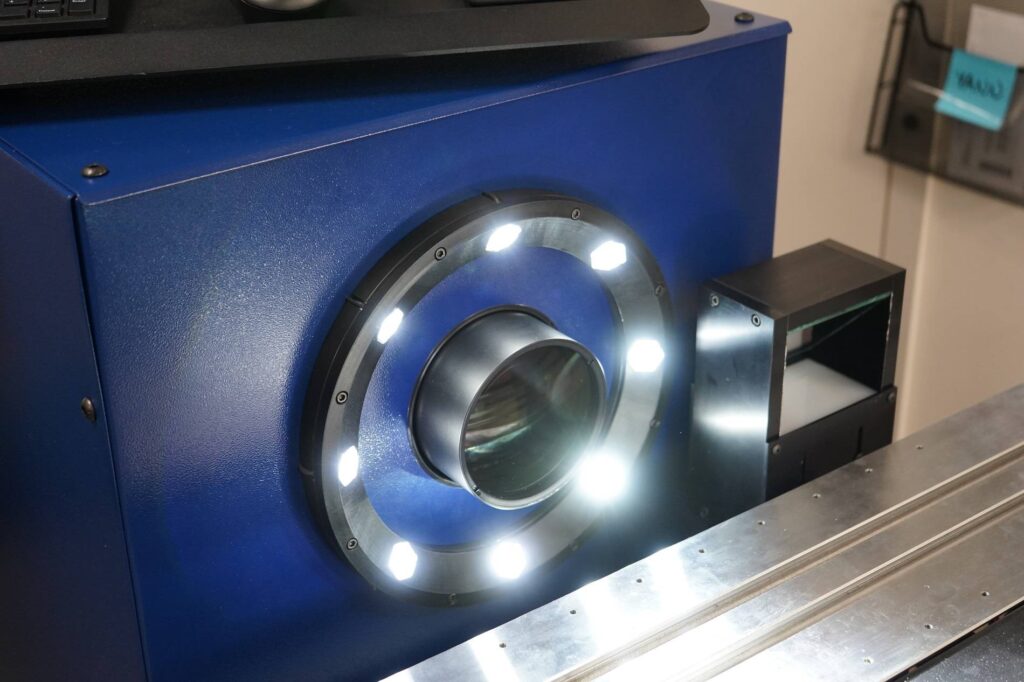

Reflected (i.e. front) illumination module or optional Octant-based Reflected Illumination

500 Series Configurations Gallery

Find the Right Digital Optical Comparator for Your Needs

The 500 Series VisionGauge® Digital Optical Comparator is a high-performing device designed for the high-accuracy inspection of a variety of parts, whether small, large, light, or heavy. This reliable inspection equipment is available in vertical and horizontal configurations and caters to a wide range of industrial applications.

Learn more about the 500 Series digital optical comparators or other devices from the VisionGauge® digital comparators collection. Contact us to request pricing details or for additional product information.