400 Series Desktop Inspection and Measurement Systems VisionGauge® Digital Optical Comparator

The 400 Series VisionGauge® Digital Optical Comparators are innovative desktop inspection and measurement systems in a compact format.

- Compact design with a large measurement envelope (up to 12" x 12")

- 3 axis inspection and measurement with manual stage movements

- Available in horizontal and vertical configurations

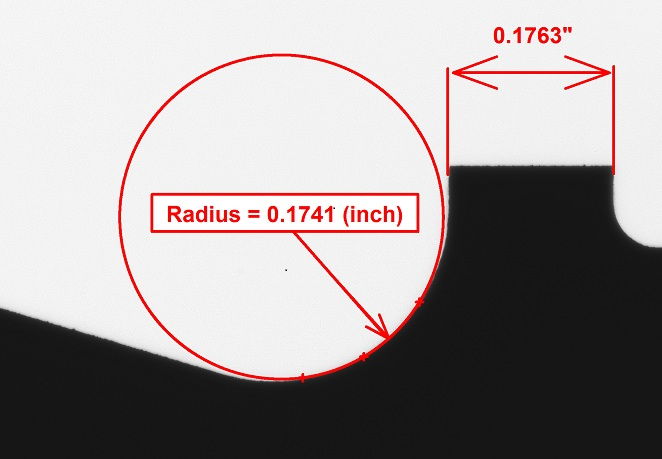

- Single magnification, precision optics with extended depth-of-field and long working distance

- Extensive set of inspection tools

- Ultra-bright all-LED computer-controlled illumination

- Optical accuracy better than +/-0.00015" (i.e. 4 μm)

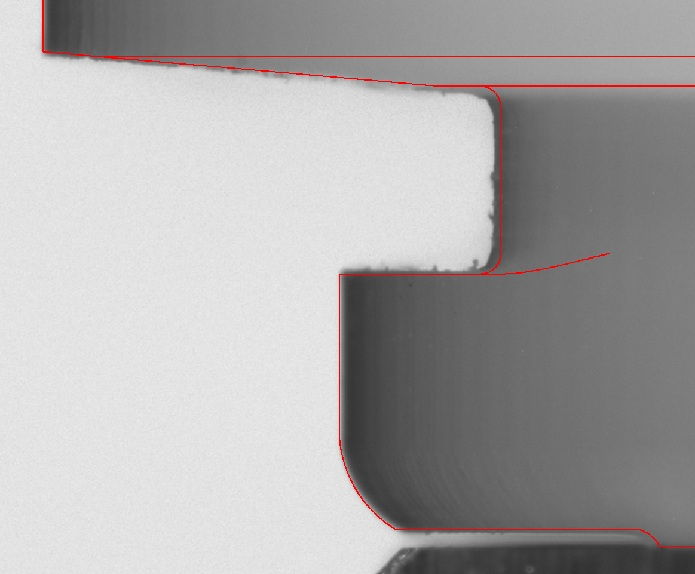

- Compare parts to their CAD file beyond the optical field-of-view, across the entire stage travel!

400 Series Desktop Optical Comparator

The 400 Series VisionGauge® Digital Optical Comparator is a state-of-the-art inspection and measurement device. This desktop optical comparator is suitable for low-throughput applications.

The optical inspection system is designed with vertical and horizontal configurations and features manual stage movement across three axes for operator-driven reliability. Despite its compact size, this high-performing device offers high resolution, precision optics, and computer-controlled, ultra-bright LED illumination for sharp and clear images. It comes with a single high-resolution monitor that allows a full view of the entire image.

The 400 Series is a cost-effective inspection and measurement system with a complete set of features. It's equipped with all the advanced and patented software capabilities VisionGauge® systems, including:

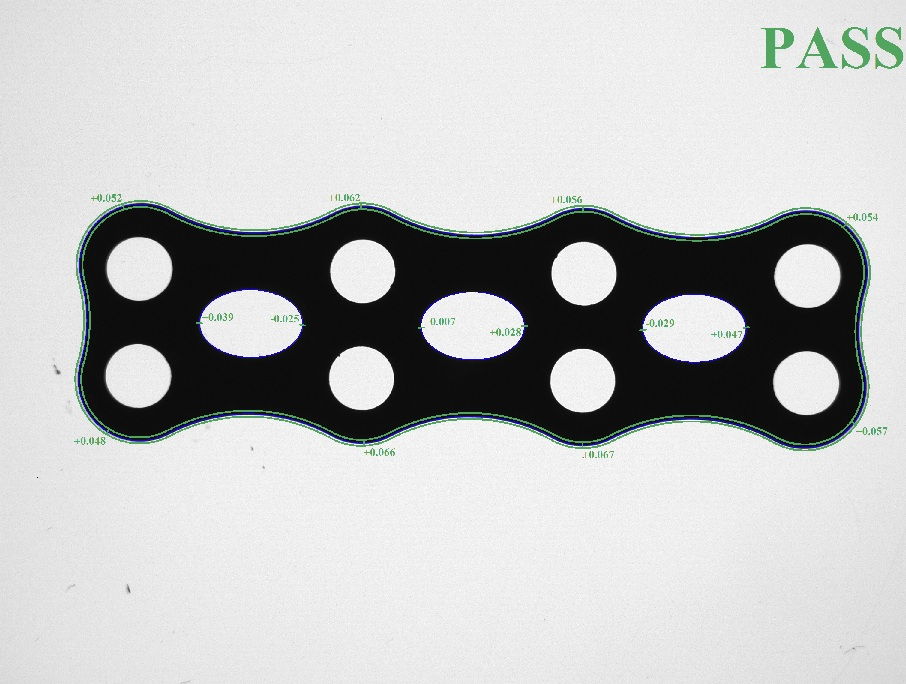

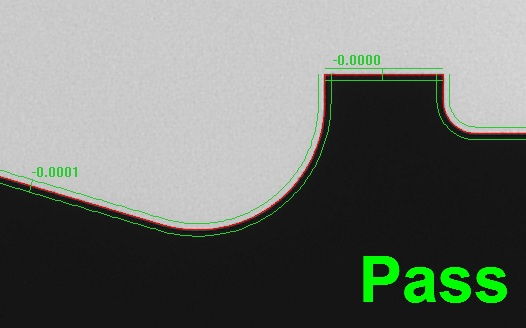

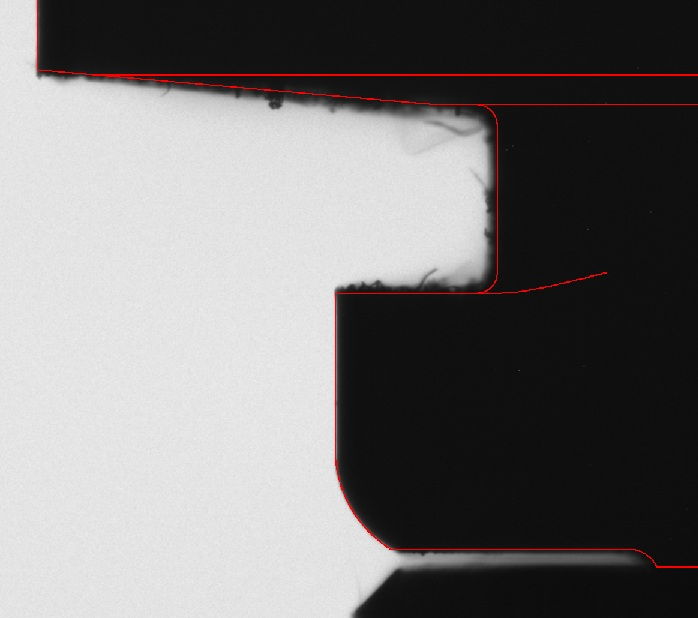

- CAD Auto-Align™: This patented groundbreaking tool automatically aligns a CAD overlay to a specific part during inspection. Within seconds, it can produce repeatable results even without operator supervision, drastically reducing inspection time and improving measurement accuracy.

- CAD Auto-Pass/Fail™ technology: The CAD Auto-Pass/Fail™ tech automatically determines whether a part is within tolerance or deviates from nominal in real time and with great accuracy.

- Tooth Checker™: Designed to check parts with teeth, the patent-pending Tooth Checker™ tool automatically locates the crests and roots in the inspected part's teeth or threads. It helps determine if the parts fall within their specified tolerance band. This tool also works for parts larger than the field of view and can be used in manual and fully automated modes.

Advantages of Our Desktop Inspection and Measurement System

This desktop optical comparator is a versatile machine equipped with automatic data collection technology. It can obtain images, gather data, and generate reports without operator-to-operator variation. It's a convenient tool offering advantages over traditional comparators. These advantages include:

- Small footprint: This device features a compact tabletop structure that can accommodate a variety of parts and fixtures. Its space-saving design makes it ideal for inspections conducted within the shop floor or manufacturing facility.

- User-friendly interface: The device is built with an intuitive operator interface that ensures accurate results while remaining easy to set up and use.

- Flexibility: Single magnification and precision optics, combined with the extended depth of field, allow a long working distance for maximum flexibility.

- Convenience: This device's built-in statistical process control and data exchange capabilities make reporting results easy and convenient. It automatically prepares reports on all collected images, measurements, and statistics for thorough documentation.

Features

Our optical inspection systems are continuously being improved with updates. The constant innovation enables us to cater to a wide range of industrial inspection applications with enhanced speed and accuracy. Our device's features include:

- The VisionGauge® extensive set of software tools for accurate measurements and image analysis

- 12" x 12" measurement envelope

- Manual storage movement and inspection on 3 axes

- 0.25-micron resolution encoders on the X and Y axes

- Ultra-bright, repeatable LED computer-controlled illumination

- Robust design with no consumable parts

- Optional LASER module for Z-axis height measurements

- Customizable optical configurations and workholding

Discover Our Desktop Optical Comparators

When it comes to optical inspection technology, the 400 Series VisionGauge® Digital Optical Comparator leads the industry with its high-performing features. This cost-effective device is built with advanced capabilities and benefits for efficient quality control in various manufacturing operations. It's suitable for a wide range of industrial applications. Our system simplifies checking parts, obtaining Pass/Fail results, and collecting detailed reports for optimized inspection processes.

Contact us for the prices of our benchtop optical measurement system, or request more information about the 400 Series VisionGauge® Digital Optical Comparator below.