VISIONx INC. is pleased to announce that Brandon Freitas Perreira, P.Eng., has been named General Manager of the company, effective January 27th, 2025.

Brandon joined VISIONx in 2016 in the role of Application Engineer and was promoted to Applications Manager in 2019. Since joining the company, Brandon has worked on a great many customer projects across a very wide range of industries including: medical, aerospace, semiconductor, turning, general machining, packaging, PCB, micro-machining, grinding, power generation & Industrial Gas & Turbines (IGT), Automotive, Coating, ultrasonic machining, fasteners, and many, many more… Through his Application Engineer work, Brandon has been exposed, over and over, to the company’s customers preoccupations: the customer’s reality, the customer’s perspective, the customer’s constraints, the customer’s requirements, etc… Brandon’s has a deep understanding of and sensibility for our customer’s point-of-view and perspective.

During his time with the company, Brandon has also developed a deep knowledge of VISIONx’s product line. It’s fair to say that Brandon has applied pretty much every tool of every system across our company’s broad product range to successfully solve the wide range of customer applications to which he has been exposed. Throughout the many projects on which he has worked, Brandon has shown an uncanny ability for adapting the capabilities of the company’s products to meet our customer’s wide-ranging requirements. Very simply: every project on which Brandon has worked has been a success and – in all cases – customers have been delighted.

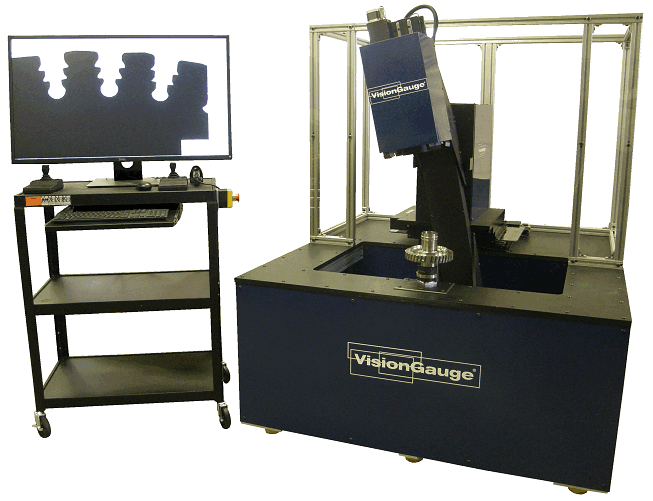

Most recently, Brandon has focused on more advanced VisionGauge® applications, including: multi-axis VisionGauge® disk inspection & measurement systems (primarily for the IGT and aerospace industries), VisionGauge® 700 Series 5-axis systems (primarily for cooling hole inspection & measurement applications) as well as various projects involving customized, complex & more advanced solutions.

In his role as General Manager, Brandon will be responsible for all the company’s day-to-day operational activities, including:

- Production (including: Machining, Assembly, Purchasing & Inventory, Quality Control, Etc.)

- Service

- Support

According to Patrick Beauchemin, founder and president of VISIONx, “Brandon’s nomination as General Manager is very forward-looking and part of a company reorganisation, to position the company for what lays ahead. Brandon’s nomination as General Manager will help support the company’s ongoing & continued growth. Like everyone at VISIONx, Brandon has – to a very high degree – a wonderful customer-centric attitude and I’m certain that – in collaboration with everyone else in the company – he’ll do a great job running the company’s operations to ensure that customer expectations are met, in every aspect and in all their dealings with our company.”