Part inspection is critical in the medical manufacturing industry to verify parts conform to strict requirements. From surgical tools to pacemakers and knee replacements, devices used on or in the human body call for extra attention to detail before reaching the market.

The visual inspection of medical parts is critical to quality and safety but lacks precision. General machine vision systems work well in controlled environments with known variables, however, medical devices come in a range of shapes and materials with unique surfaces that add new variables to the equation. VisionGauge® Digital Optical Comparators use advanced optical technology in the magnification and analysis of parts within medical devices to ensure they comply with specifications and any relevant quality standards.

Medical Equipment Inspection

Medical equipment is designed with precision in mind. Each device and component must meet exacting specifications to serve its purpose safely and effectively, making medical equipment inspection crucial.

Medical manufacturing part inspection comes in many forms. Some examples of applications the VisionGauge® Digital Optical Comparator is already being used to solve are:

- Stent inspection and measurement: Stents call for critical precision due to their placement in the human body. Unbiased stent measurement tools are key to inspecting them quickly and accurately.

- Plastic and polymer implant inspection: From total hip replacements to facial reconstruction implants, many medical devices are made with plastic and polymer. These materials allow for the fabrication of complex parts with unique geometries, but they can add glare and reflections that make inspections challenging with traditional optical comparators.

- Bone screw inspection: Medical bone screws are instrumental in fixing fractures together for proper healing. The spacing and pitch of each thread are critical, so medical device parts inspection requires specialized tools.

- Orthopedic implant inspection: Orthopedic implants are common throughout the body, from knees to shoulders. Each implant’s specifications depend on its purpose. Through inspection, manufacturers can confirm that implants are free of defects and aligned with the relevant standards.

- Medical rasp inspection and measurement: Like implants, medical rasps and other surgical tools have little room for manufacturing errors. The height, spacing, angle, and bottom radius of each tooth must be within the appropriate tolerance band.

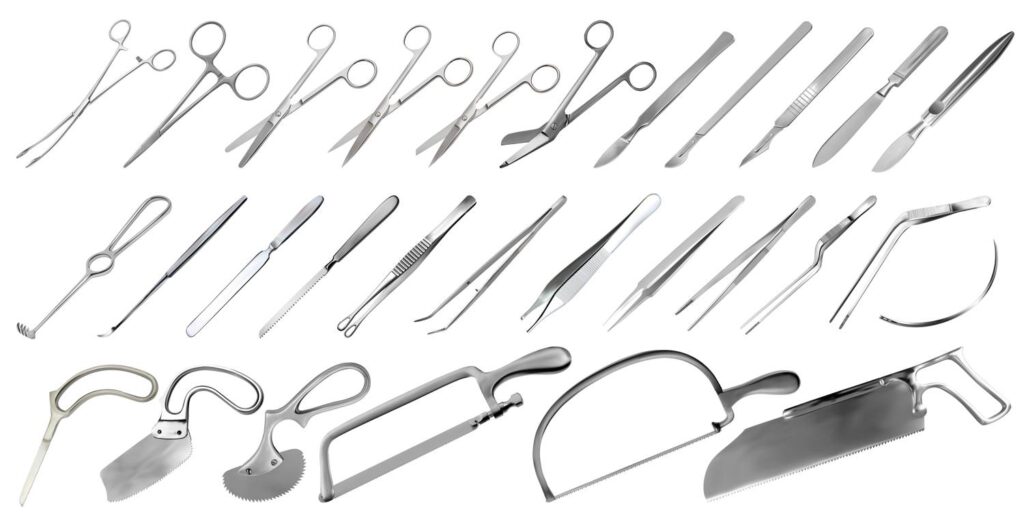

- Medical/Surgical instrument inspection and measurement: The instruments and tools used in medical and surgical procedures are also subject to strict quality standards to ensure all their design requirements and dimensional characteristics are to specification.

Digital Optical Comparators for Medical Parts Inspection

VISIONx, Inc. provides a range of digital optical comparators in vertical and horizontal configurations to accommodate multiple applications. These systems are ideal for orthopedic parts inspection and medical device parts inspection, helping manufacturers streamline the process while lowering costs and improving product quality.

The VisionGauge® Digital Optical Comparator line offers increased accuracy, higher throughput, and a smaller footprint than traditional comparators and other existing technology. VisionGauge® systems compare medical devices and components directly against their CAD data to ensure compliance. These tools issue results in the form of Pass or Fail / Go or No-Go to simplify the inspection process.

Manufacturers can also use the VisionGauge® Tooth Checker™ for medical rasps, bone screws, and other devices and components with teeth or threads. The tool automatically locates crests, roots, or both and determines whether they are in tolerance and safe for use. Additional screw threads measurements tools are also available to reliably and quickly measure and report screw dimensions.

VisionGauge® system validation is straightforward to ensure all industry and governing body requirements and standards are met. VisionGauge® systems are also fully capable of collecting complete electronic documentation for device history.

Explore the 500 Series

The 500 Series Digital Optical Comparator sets the standard for optical quality control equipment everywhere. This machine can handle almost any demand thanks to its high efficiency, user-friendly design and precision optics.

Reliable Systems for the Medical Manufacturing Industry

When quality and precision count, VisionGauge® delivers. Reach out for more information about the ideal type and configuration for your medical equipment inspection needs.