VisionGauge® Digital Optical Comparators For Advanced Inspection

Founded in 1996, we deliver high-quality, accurate, and efficient inspection solutions tailored to enhancing the digital inspection experience. Rely on our expertise in Vision Inspection Systems, and discover the power of VisionGauge® Digital Optical Comparators.

Digital Optical Comparator Manufacturing

500 Series

600 Series

700 Series

300 Series

400 Series

StandAlone Inspection

Disk Inspection

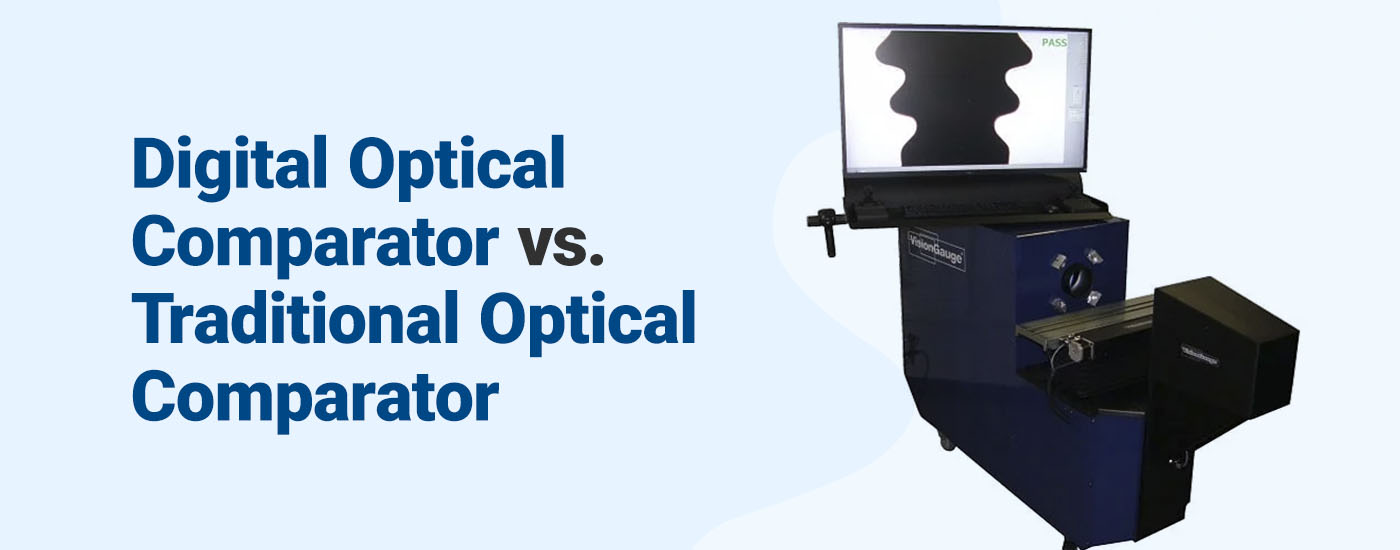

VisionGauge® Digital Optical Comparators

The Fastest, Easiest, Most Accurate Way to Compare a Part to a CAD File™

- Much more accurate,

- Much faster,

- Much more powerful,

… than any other existing optical comparator - Available in horizontal, vertical, compact, and extended configurations

600 Series VisionGauge® Compact Desktop System for Turned Parts

- Designed to check turned and rotationally symmetrical parts, such as screws, bolts, shafts, and more…

- 2 motorized encoded axes of motion – rotation and vertical movement of the part

- Measure turned parts with optical accuracy better than +/- 0.00015″

- Includes VisionGauge® advanced software toolset and patented technology

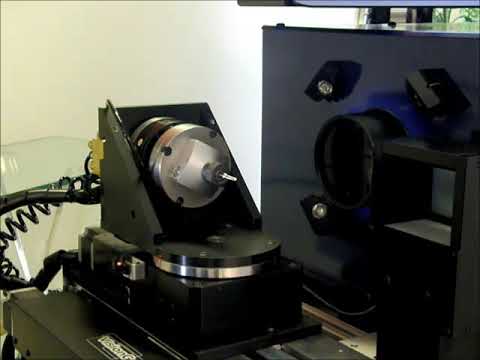

700 Series VisionGauge® 5-Axis Inspection and Measurement Systems

The perfect solution for checking EDM & laser-drilled holes

- 5 axes of motion to properly view parts from all sides and angles

- Fully-Automated operation

- Optimal for complex aviation, aerospace, power applications, and parts with complex geometries

- Fast, accurate, and easy-to-use

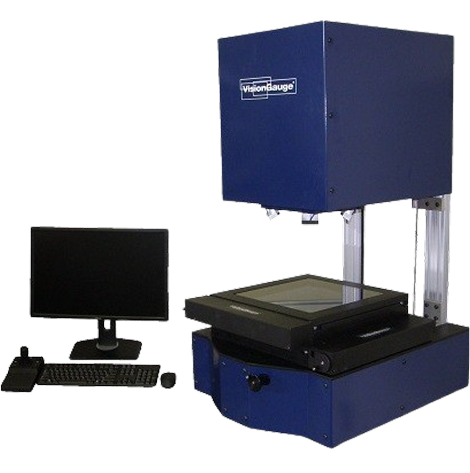

300 Series VisionGauge® Field-of-View Systems

Cost-effective, easy-to-use, field-of-view systems that are ideal for smaller parts

- Perfect for small parts that fit in the field-of-view

- Needs no overlays, templates, or Mylars™

- Check multiple parts regardless of their orientation

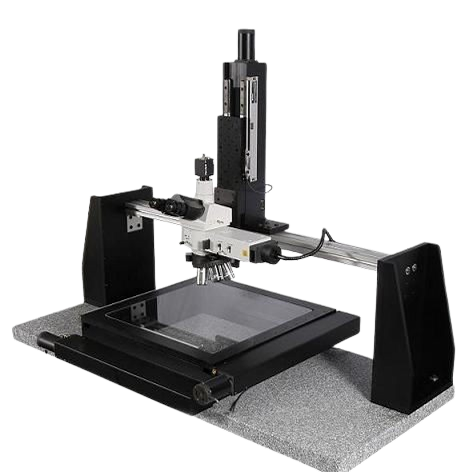

VisionGauge® Desktop Inspection and Measurement Systems

The Fastest, Easiest, Most Accurate Way to Compare a Part to a CAD File™

- 3-axis inspection and measurement system with manual stage movements

- Compact desktop system with large measurement envelope

VisionGauge® StandAlone Inspection & Measurement Systems

Designed specifically for carrying out high-accuracy inspection and measurements in automation applications

- Widely-applicable and extremely general purpose

- Has all VisionGauge® advanced inspection and measurement capabilities, including our patented CAD Auto-Align™ and CAD Auto-Pass/Fail™ tools

- Can easily be dropped into an existing automated cell

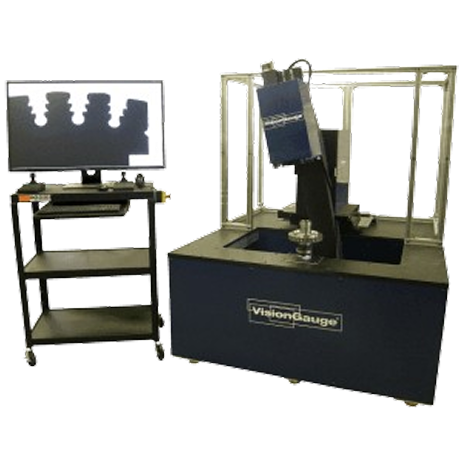

VisionGauge® Disk Inspection Systems

- The ideal solution for companies that manufacture and inspect turbine disks

- Perfect for checking turbine disk slots (both normal and at an angle)

- Has all VisionGauge® advanced inspection and measurement capabilities, including our patented CAD Auto-Align™ and CAD Auto-Pass/Fail™ tools

Our VisionGauge® Digital Optical Comparators

Thanks to a reliance on digital technology and automation, our solutions are more accurate than traditional optical comparators. Our VisionGauge® Digital Optical Comparators make it easy for you to directly compare your manufactured parts to their CAD data without operator error. The process is fully automatic, saving both time and money.

Our VisionGauge® Digital Optical Comparators offer a more efficient user experience and have a smaller footprint than traditional optical comparators. We also have experience customizing systems for customers who need to meet certain specifications. Explore our site to find out what options we have available!

Vision Systems for Quality Inspection

Our optical measuring systems provide an efficient metrology solution that will help you gauge the quality of parts using cutting-edge imaging technology. Our measuring equipment is convenient and intuitive, allowing users to measure a variety of products and parts.

VisionGauge® inspection and measuring systems can help you verify your parts and detect inconsistencies and defects with characters, patterns, edges, and more. They can be fully automated and are compatible with our high-performance VisionGauge® machine vision software. Learn more about our visual inspection equipment and vision measurement systems.

These systems are designed to improve inspection performance and increase your output of high-quality parts. View our optical measuring systems for more information about our metrology and optical products.

Capabilities & Software

Our Machine Vision Software

Our Automation Capabilities

We deliver more than most machine vision system companies, setting the standard for technology in our industry. You can use our VisionGauge® OnLine software to collect, store, and analyze data based on images of your parts. These software solutions come with a variety of features and tools to help you efficiently automate your measurements and inspections.

VisionGauge® is an operator-oriented option that collects and reports measurement data for product testing applications, while VisionGauge® OnLine can be used to automate both in-line and off-line applications. Learn more about the features and benefits our platforms offer with our machine vision software.

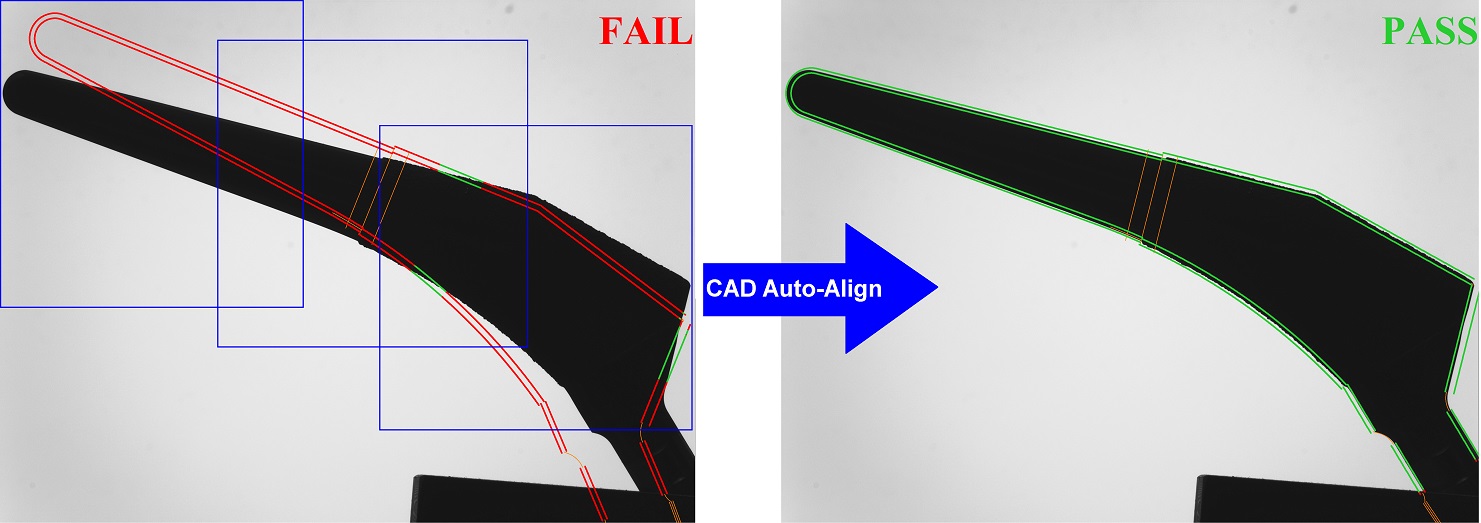

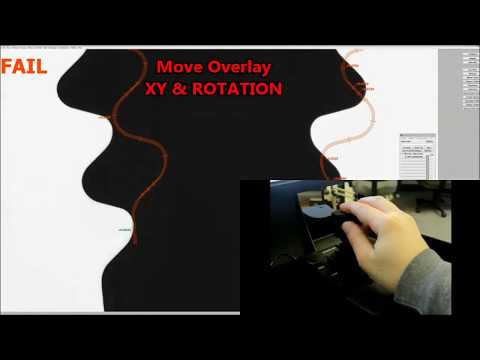

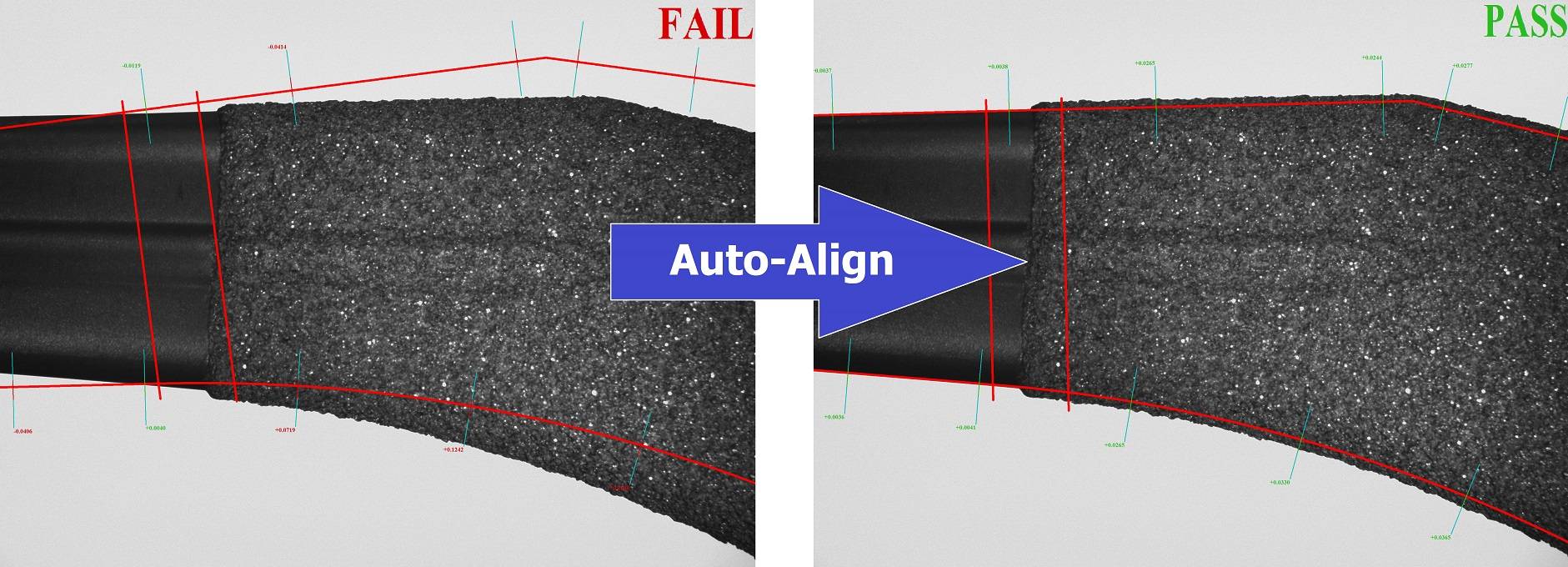

Our VisionGauge® systems include our groundbreaking, patented technology such as our CAD Auto-Align™ and CAD Auto-Pass/Fail™ tools, making our systems repeatable and easy to use directly on the shop floor. The CAD Auto-Align™ tool automatically aligns the overlay for a fully automated CAD-to-part comparison. Meanwhile, the CAD Auto-Pass/Fail™ tool computes and displays any deviation from nominal and determines out-of-tolerance measurements in real time. Many other proprietary patented software tools are also available and constantly in development to meet strict inspection requirements.

VisionGauge® systems have automation capabilities that offer accurate hands-off operation and easy interfacing with external machinery and equipment, if required. We designed our systems to provide extensive communication through a wide range of protocols that support two-way handshaking — such as TCP/IP over Ethernet and digital I/Os.

You can record all of your quality control automation thanks to our robust data collection, reporting, and exchanging. Our quality automation insights offer detailed visibility into your production line to help you improve operations and make more informed decisions.

Versatility is one of our strengths, and we make sure you can incorporate the high-accuracy measurements of VisionGauge® with fully-automated production. You can even drop our systems into an automated cell for sophisticated measurements and inspections. You’ll get the quality assurance you need while minimizing labor requirements and complexity. VisionGauge® inspection automation delivers these benefits for ongoing operations and implementation, allowing you to stay flexible and efficient.

Contact Us About How You Can Improve Your Inspections

Are you interested in streamlining your inspection process with VisionGauge® Digital Optical Comparators and optical measuring systems? As your vision inspection system manufacturer, we’re available to provide support at any time, so browse our selection of products or contact us online today.